Real information ! ! tell you how to produce alkyd resin

Aug 26,2019

Aug 26,2019

JCT

JCT

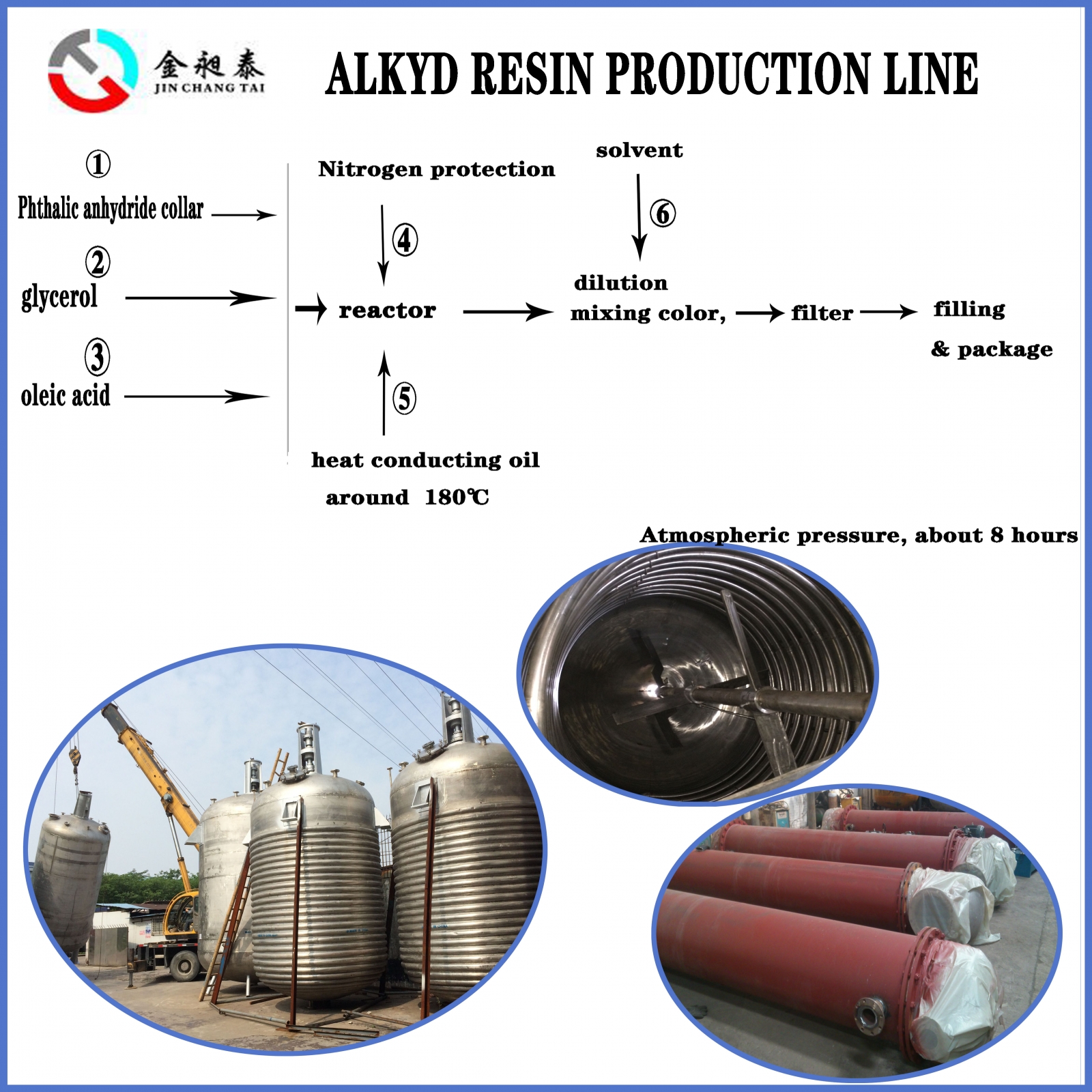

Real information ! ! tell you how to produce alkyd resin coil reactor .

Alkyd resin is the main raw materials for making the oil base paint ,but many people don’t know how to produce alkyd resin , according to the 20 years experience ,we sharing the process information below:

1. First of all the monomers put into coil reactor, small amounts of antioxidants, opening speed agitation (first open slow speed , let polymerization steady, smooth reaction).

2. temperature raised to 180 ℃ with 2 hours ; keep warm for 1 hour. then heated up to 200-220℃ with 2 hours ,keep warm for 2 hours,

3. Take the sample form the reactor valve, test the acid value measurement ,when acid value reach standard then go for next step . if failure keep warm continue. retest sample every 30 minutes.

4. Polyester is easy to be taken the measure that heat up the temperature Gradually, maintain the normal effluent rate, should avoid too violent reaction caused by entrained material, and influence monomer ratio and resin structure. keep temperature and time is depending on the formulation, but also related with the Oil product and oil degree .

5.After reaching the end point, heating was stopped and, after cooling put down solvent added to the kettle slowly. The polyester reaction need pay attention to the rate of effluent follows the rate of effluent, according to a predetermined sampling time, measure acid number and the viscosity , after reaching a predetermined cooling, dilution, filtered to prepare a paint.

6.Finally stir, filter 60-70 ℃, flow to the storage tank.

More information ,please contact me .

Alkyd resin synthesis apparatus main

drop tank →reactor → condenser → trap→ filter → filling

heating system: oil heating, optionally jacketed reactor / reactor outer coil

cooling system: cooling with cold water

stirring speed first slow after the fast, you need to drive with.

CN

CN

HOME

HOME Discussion on the selection of practical materials for vacuum kneading machine!

Discussion on the selection of practical materials for vacuum kneading machine!  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address